What are the Parts of Solar Panel?

Solar energy, which comes from sunlight, is free and eco-friendly. Solar panels convert sunlight into electricity. In this article, you’ll learn about the main parts of solar panel, and in the next one, you’ll discover how solar panels are made.

Parts of solar panel contributes to the panel’s efficiency, from the photovoltaic cells capturing the sun’s rays to the sturdy metal frame providing structural integrity and the protective glass enclosure ensuring longevity.

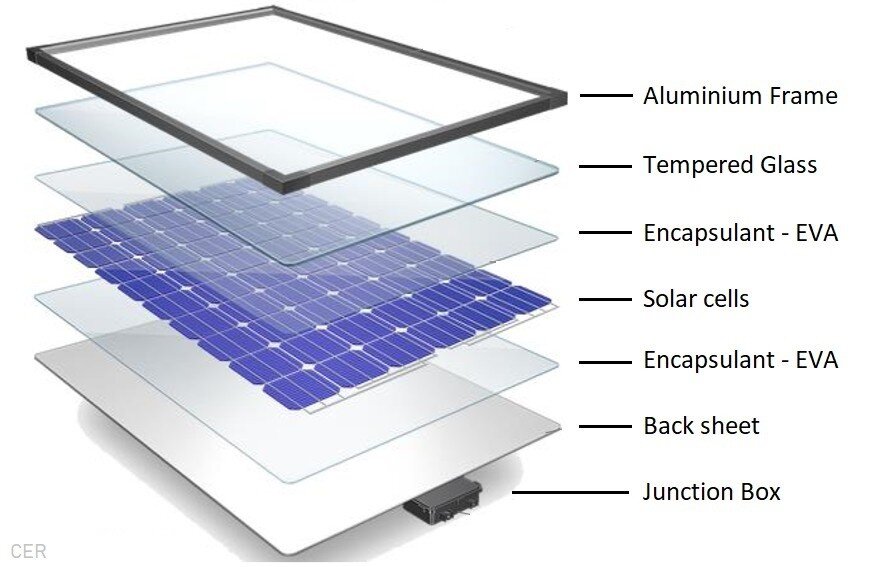

What are solar panels made of?

Solar power systems have different components and each one has specific jobs. These component works together in order to provide the best service possible. Parts of solar panel and their functions are the following:

A solar panel system has various parts and components that make up a complete system for your home or business. The major parts here include:

- Solar glasses

- EVA

- Back sheets

- Aluminum frames

- Junk box

- Connector

- Silicone glue

Solar glass:

EVA films cover the solar cells. Then, place a glass sheet on the front side of the panel. The cells are exposed to sunlight here.

The glass provides protection from the elements, such as weather, dust, rain, and hail. The material is usually high-strength tempered glass, about 3-4mm thick, and built to endure mechanical loads and extreme temperatures.

To meet the IEC minimum standard impact test for solar panels, the glass sheet must be able to endure hail stones with a diameter of up to 1 inch, traveling at speeds of up to 60 mph. Additionally, solar cells can reflect up to 35% of the sunlight that falls on their surface, which can negatively impact their efficiency.

To minimize reflection, the back of the glass is treated with anti-reflective chemicals such as graphene, titanium dioxide, and silicon nitride. This special coating helps stop sunlight from bouncing off the panels, so more sunlight can reach the cells. This makes the panels work better and more efficiently.

Back Sheet:

The solar cells are covered with EVA films first. Then, a glass sheet is placed on the front side of the panel. At last, a back sheet is affixed to the backside of the panel. At last, a back sheet is affixed to the backside of the panel. This layer serves as a moisture barrier, providing mechanical protection and electrical insulation for the solar cells.

Back sheets are made from various types and qualities of polymers or plastics. Every kind offers different degrees of safeguarding, heat stability, and enduring resistance to UV rays. The backsheet layer is typically white, but it can also be clear or black. This depends on the company and the manufacturing process of the module.

EVA:

EVA is a type of polymer used in solar cell production. It is a transparent plastic layer. This layer encapsulates the solar cells. It also secures them in place during production. It is crucial for the long-term performance of solar panels as it is highly durable and able to withstand extreme temperatures and humidity, preventing moisture and dirt from entering.

The EVA layer is put on both sides of the solar cells. It absorbs shocks and protects the cells and wires from damage. Vibrations or impacts, such as hail or other objects, can cause this damage. A strong EVA film is important for keeping the solar panel in good condition and stopping water from getting inside.

In the manufacturing process, the cells are first encapsulated with EVA before being assembled into the glass and back sheet.

Back Sheet:

The workers add a layer of material called a back sheet to the back of the solar panel. It serves as a barrier against moisture and a shield for both mechanical protection and electrical insulation.

Different types and grades of polymers or plastics are used to make the back sheet. Each type offers varying levels of protection, thermal stability, and long-term resistance to UV radiation. The back sheet layer is usually white. It can also be clear or black. This depends on the manufacturer and the style of the module.

It forms a rare host layer of the panel providing both mechanical protection as well as electrical insulation.

Aluminum frame:

The aluminum frame serves several purposes. It protects the edges of the laminated section around the cells. It provides a strong structure for mounting. It also keeps the panels in shape and position. To ensure they can withstand extreme stress and loading from high winds and other weather impacts, these frames are typically designed to be lightweight, stiff, and durable.

The weight of the solar module is mainly determined by the aluminum frame, available in either silver or anodized black. The manufacturer may also coat the frame with additional elements such as silver or nickel. During assembly, you can screw, press, or clamp the corner sections of the frame together. This will help you achieve different levels of strength and stiffness.

Solar cells:

Solar cells are the main component responsible for converting sunlight directly into electricity. They usually have a rectangular or hexagonal shape and consist of purified and crystallized silicon. Thin wires called fingers and busbars connect the cells and carry electricity to power appliances.

Solar cells have different designs, colors, technologies, and configurations. These factors play a significant role in determining the efficiency rating and durability of the cells. Multiple solar cells arranged together and connected with busbars and fingers form a solar module. These modules are available in different sizes, ranging from 60 to 144 cells or more.

Aluminum frame:

The aluminum frame serves several purposes. It protects the edges of the laminated section that encloses the cells. It also provides a strong structure for mounting. Additionally, it helps keep the panels in shape and position.

These frames are designed to withstand strong winds and other weather conditions. They are typically lightweight, rigid, and durable.

The weight of the solar module is significantly impacted by the aluminum frame, which can be either silver or anodized black. The frame may also be coated with additional elements such as silver or nickel, depending on the manufacturer. The corner sections of the frame can be screwed, pressed, or clamped together during assembly to provide varying levels of strength and stiffness.

Junction box:

The junction box is a tiny, weather-resistant box at the back of the solar panel. It’s where the cables connect the panels together. This box is crucial because it’s where all the solar cells are linked, and it needs to be shielded from water and dirt.

The junction box contains conductive connection points and busbars that gather the electricity produced by the solar panels. This electricity is then sent through cables to the external circuitry or battery bank to use it on cloudy days.

Therefore, the cover of the junction box can usually be opened or removed for servicing. However, as solar panel technology has advanced, junction boxes have also improved to better perform their functions. Modern solar panels often feature advanced and durable diodes, along with junction boxes that don’t require servicing.

Connectors:

Solar panels are typically linked together using MC4 connectors, which are specialized weather-resistant plugs and sockets. MC4 stands for multi-contact 4mm diameter connector. These connectors are made to last, resisting damage from UV rays and staying strong even under high voltage conditions up to 1000V. They’re built to maintain a steady connection with very little resistance, whether the voltage is low or high.

Silicone Glue:

In solar panels, the most important material used is silicon. This material forms strong bonds and is very resistant to moisture, chemicals, and changing weather conditions.

It is ideal for assembling solar panels. Additionally, silicon is a prevalent semiconductor material commonly used in electronic devices. Hence, silicon glue is frequently employed in the manufacture of solar panels. It is most commonly used in solar cells and creates a strong bond and is resistant to chemical moisture and other weather conditions.

Contact Our Friendly, Knowledgeable Staff

Solar Earth Inc., with expertise and certifications, empowers your home for enhanced energy generation. Contact us today to transform your home into a sustainable, long-term renewable energy source.